Xylan Coating Services for Industrial Applications

High-performance, low-friction coatings designed to protect, extend equipment life, and optimise production.

What Is Xylan Coating?

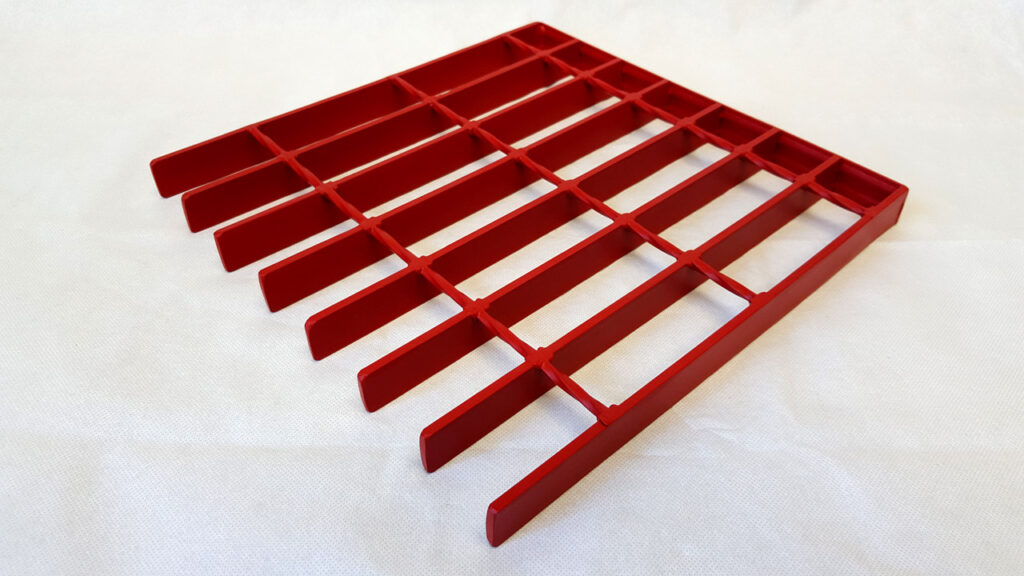

Xylan is a family of high-performance fluoropolymer coatings known for their exceptional non-stick, low-friction, and chemical-resistant properties. Ideal for use in demanding industrial environments, Xylan coatings improve component durability, reduce mechanical wear, and ensure long-term surface protection—even under extreme conditions.

Why Choose Xylan Coatings from Marcote?

At Marcote, we apply precision-engineered Xylan coatings to help manufacturers overcome operational challenges, reduce downtime, and meet stringent quality standards.

- Non-stick surface: Reduces food/product adhesion and minimises cleaning cycles

- Low friction: Improves efficiency in moving components and machinery

- Corrosion & chemical resistance: Ideal for aggressive or high-moisture environments

- Temperature stability: Performs in both high-heat and cryogenic settings

- Food contact compliant options: Safe for use in food and pharmaceutical applications

Where Xylan Coatings Are Used

Xylan is part of a family of fluoropolymer coatings, including PTFE and PFA, which offer outstanding durability and surface performance across a wide range of industries where performance, longevity, and reliability matter:

- Food & Beverage: Bakeware, cutting blades, and conveyor systems

- Automotive: Piston rings, brake callipers, and suspension parts

- Oil & Gas: Fasteners, seals, and valves exposed to corrosive environments

- Aerospace: Bearings, fasteners, and structural components

- Pharmaceutical: Mixing vessels and cleanroom-compatible equipment

How We Apply Xylan Coatings

Xylan coatings are applied in liquid form using a high-volume, low-pressure (HVLP) spray system to ensure a smooth, even finish. Before coating, all surfaces are carefully prepared through sandblasting, creating a clean, etched surface that improves adhesion.

Once applied, the coated part is baked at controlled temperatures, allowing the coating to cure and form a tough, durable, and chemically inert finish.

Thanks to their advanced fluoropolymer composition, Xylan coatings offer low friction, non-stick performance, and excellent resistance to heat, corrosion, and chemicals—making them ideal for a wide range of demanding applications across multiple industries.

Compatible Substrates

Our Xylan coatings are suitable for:

- Carbon & stainless steel

- Titanium & magnesium

- Aluminium & copper alloys

- Glass fibre & plastics

- Rubber, carbon fibre,

- and more (enquire below for info)

Why Work with Marcote?

With over 30 years’ experience, we don’t just coat components—we help you solve production problems. Whether you need to prevent sticking, reduce maintenance, or increase equipment reliability, we’ll work with you to find the right coating for the job.

Ready to reduce friction and extend the life of your parts?

FAQs

Xylan coatings are ideal when you need a balance of non-stick, low-friction performance and chemical resistance in harsh environments. They’re particularly well-suited for components that experience mechanical wear, high moisture, or frequent cleaning cycles. While PTFE and PFA may excel in extreme heat or pure non-stick applications, Xylan offers a versatile solution across multiple industries.

The lifespan of Xylan depends on the operating conditions, but in most industrial settings, it significantly extends component life by reducing friction and corrosion. In applications like fasteners, seals, and cutting blades, coatings can remain effective for years before recoating is required, often outlasting untreated parts several times over.

Yes. In most cases, worn Xylan coatings can be removed, the component re-prepared, and a new coating applied. This makes refurbishment more cost-effective than replacing parts, particularly when dealing with high-value components like aerospace fasteners, precision automotive parts, or pharmaceutical equipment.

Short answer is yes. Many Xylan coatings are available in food-contact compliant grades, making them safe for use in food production lines, bakeware, and pharmaceutical mixing vessels. Their non-stick and low-friction properties also help reduce residue build-up, improve hygiene, and make cleaning cycles quicker and more effective.

Turnaround depends on the size, complexity, and volume of the components, as well as the required coating thickness. Smaller parts can usually be coated and returned faster, while larger-scale or batch applications may take longer. At Marcote, we work with clients to plan coating schedules that minimise production downtime.

Get in touch